The Fishbone Diagram: A Powerful Tool for Quality Assurance

Share

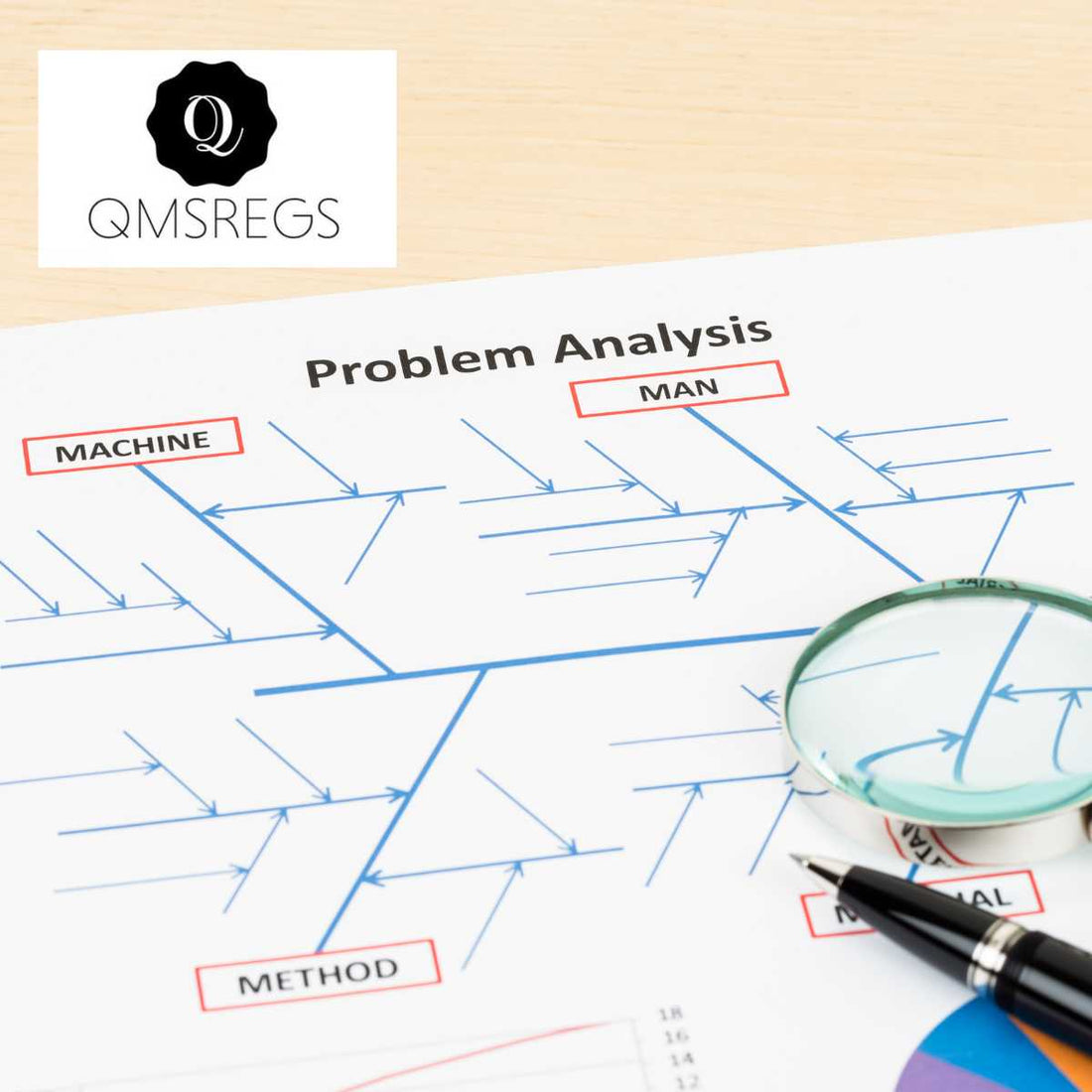

In quality assurance, identifying the root cause of problems is crucial for developing effective solutions. One of the most effective tools for this purpose is the Fishbone Diagram, also known as the Ishikawa Diagram or Cause-and-Effect Diagram. Named for its resemblance to a fish skeleton, this method provides a structured approach to problem-solving, helping teams pinpoint the origins of issues that affect product quality and process efficiency.

What is the Fishbone Method?

The Fishbone Method was developed by Dr. Kaoru Ishikawa in the 1960s. It is designed to identify the root causes of a particular problem by categorizing potential causes into major categories, which are then further divided into sub-causes. This visual representation helps teams systematically explore all possible factors contributing to an issue.

Why Use the Fishbone Diagram?

The Fishbone Diagram is particularly useful because it:

- Encourages Structured Thinking: By organizing potential causes into categories, it ensures that all aspects of a problem are considered.

- Promotes Team Collaboration: It facilitates brainstorming sessions where team members can contribute their insights and expertise.

- Identifies Root Causes: Instead of addressing symptoms, it helps teams drill down to the underlying issues, leading to more effective and lasting solutions.

- Simplifies Complex Problems: Breaking down a problem into its constituent parts makes it more manageable and easier to address.

How to Create a Fishbone Diagram

Creating a Fishbone Diagram involves several steps:

1. Define the Problem

Start by clearly stating the problem at the head of the fish. This should be a concise description of the issue you want to investigate.

2. Identify Major Categories

Draw a straight line (the spine of the fish) and create branches for major categories of potential causes. Common categories include:

- People: Human factors, such as skills, training, and attitudes.

- Processes: The methods and procedures used.

- Materials: Raw materials and supplies.

- Equipment: Machinery, tools, and technology.

- Environment: External factors, such as work conditions and location.

- Management: Policies, administrative processes, and organizational culture.

3. Brainstorm Possible Causes

Under each category, brainstorm potential causes of the problem and add them as smaller branches. Encourage open and inclusive discussion, ensuring that all possible causes are considered.

4. Analyze the Diagram

Once all potential causes are mapped out, analyze the diagram to identify which factors are most likely contributing to the problem. This may involve further investigation or data collection to validate assumptions.

5. Develop Action Plans

After identifying the root causes, develop action plans to address them. This might involve process changes, additional training, equipment upgrades, or other corrective measures.

Practical Applications in Quality Assurance

The Fishbone Method can be applied in various quality assurance scenarios, such as:

- Manufacturing: Identifying causes of defects in production processes.

- Service Industry: Analyzing factors leading to customer dissatisfaction.

- Software Development: Investigating the sources of bugs and errors in code.

- Healthcare: Exploring reasons for patient care issues.

Example: Improving Product Quality in Manufacturing

Suppose a manufacturing company is facing issues with a high rate of defective products. Using the Fishbone Method, the team might identify the following causes:

- People: Inadequate training, lack of experience.

- Processes: Inefficient quality control procedures.

- Materials: Poor quality raw materials.

- Equipment: Malfunctioning machinery, outdated technology.

- Environment: Poor lighting, high noise levels.

- Management: Lack of clear quality standards.

By addressing these root causes, the company can implement targeted improvements, such as enhancing training programs, upgrading equipment, improving working conditions, and refining quality control processes.

Summary

The Fishbone Method is a versatile and powerful tool for quality assurance. By providing a structured approach to problem-solving, it helps teams identify and address the root causes of issues, leading to more effective solutions and improved quality outcomes. Whether in manufacturing, services, software development, or healthcare, the Fishbone Diagram is an invaluable asset for any quality assurance professional.